Craft.

Every day is different in the S&A factories around the country.

During any given week, we build stairs for houses that range in size and scale, from high end stairs that belong in some of Australia’s most renowned homes, to quaint pieces in home renovations.

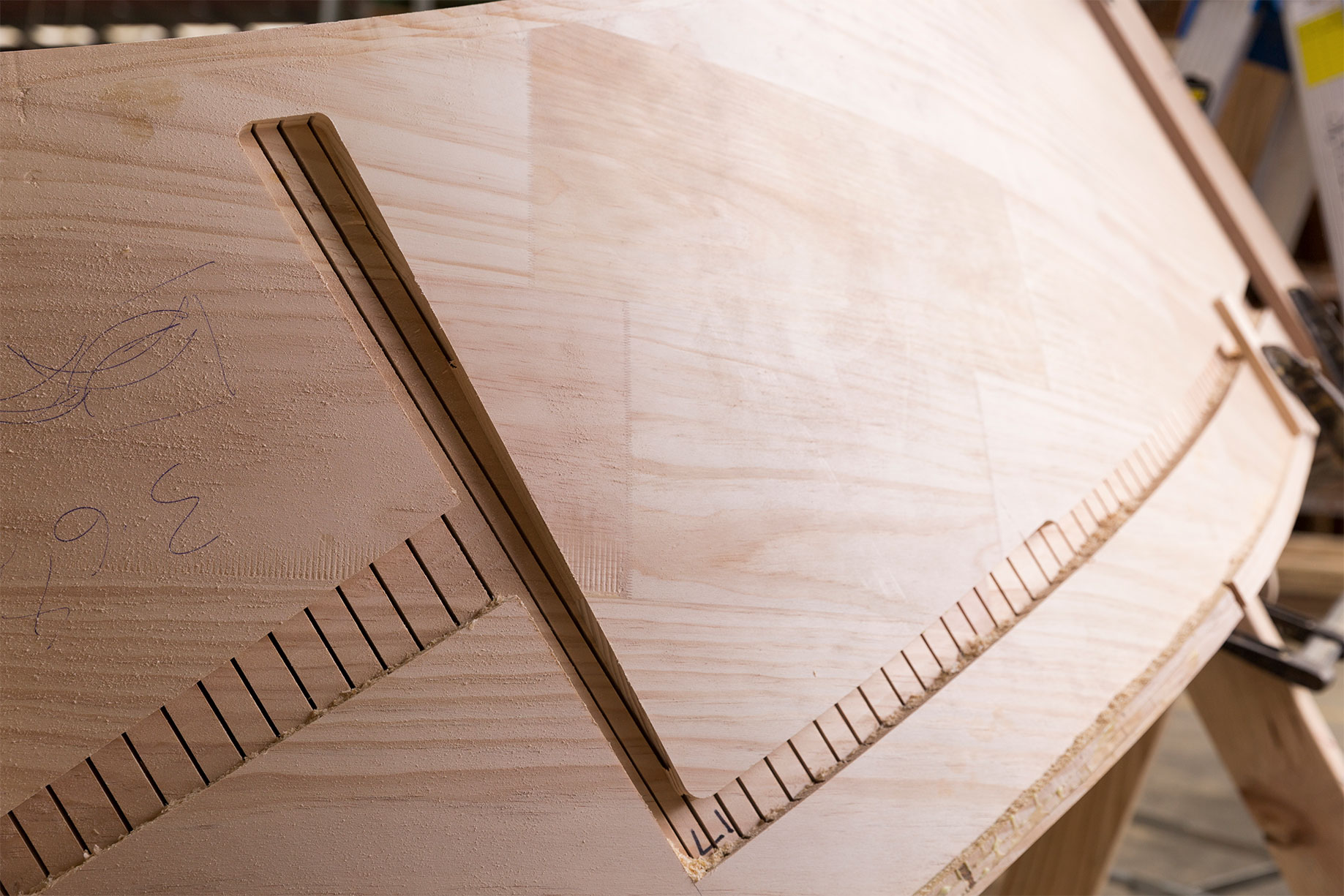

In our Melbourne factory, there’s a constant flow through the factory, from the machine shop at the east end of the factory to the assembly area at the west end. If you follow closely enough, you can watch the raw timber go through the process of machining, dressing and gluing through the machine shop, to where it is bent, cut and crafted into the shape by our highly skilled craftsmen.

Stairs are very intricate and detailed, so there’s still so much that we do by hand at the S&A factories. Along the far wall our craftsmen line the timber benches, in the same way they’ve done for almost 100 years. They use their specialist skills to add a human touch to our stairs, shaping all components including our signature continuous handrail.

One corner of the factory is entirely dedicated to the art of geometry. We glue up timber, create a cast, and then carefully mould and bend the timber around it over a number of days.

Once the timber has been stripped and sanded, finished, bent, curved and moulded, it heads out the other side through dispatch. It’s picked up by our drivers and taken to site the very next day.

In this blog post, we asked Melbourne photographer Peter Tarasiuk, to capture the movement and life on a regular day at S&A’s Melbourne factory. We are so pleased with the results.

Words by Nick Acquroff

Photography by Peter Tarasiuk